Andon Process Summary (Infographic)

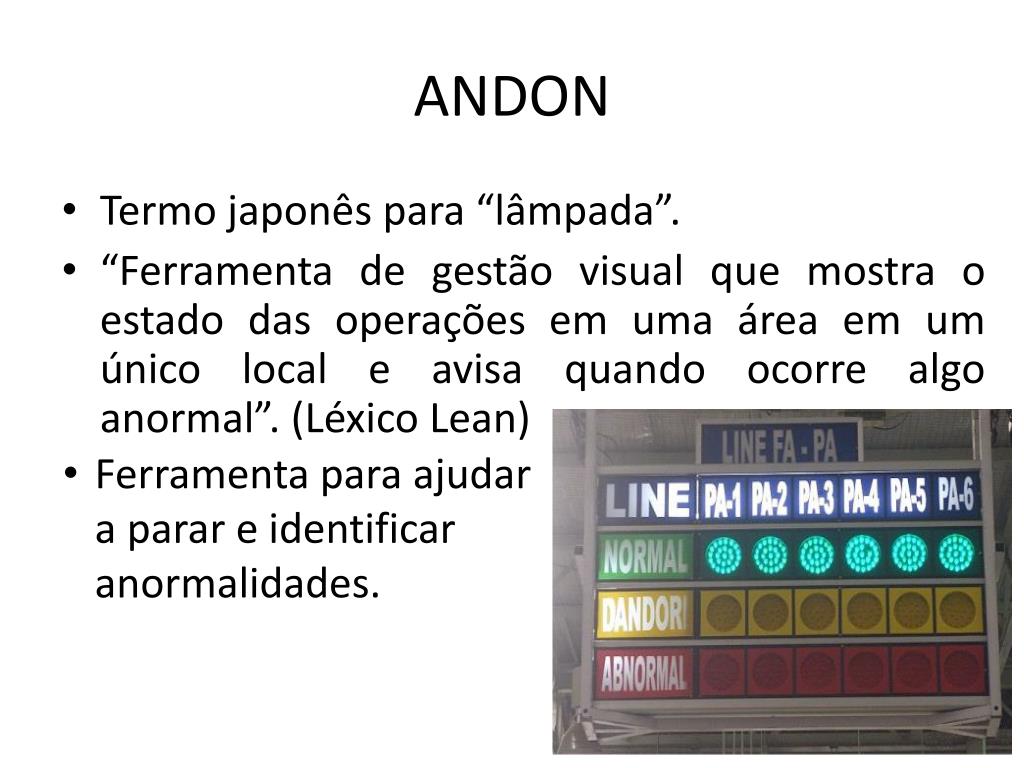

Jan 05, 2020. 190 likes | 234 Views. Andon (Process Control Board). Andon. Japanese translation: Lantern. What is Andon ?. A visual control that enables the operator to inform the Team Leader (or responsible line cover) that an abnormal condition exists. Download Presentation. line.

The Andon Process MudaMasters

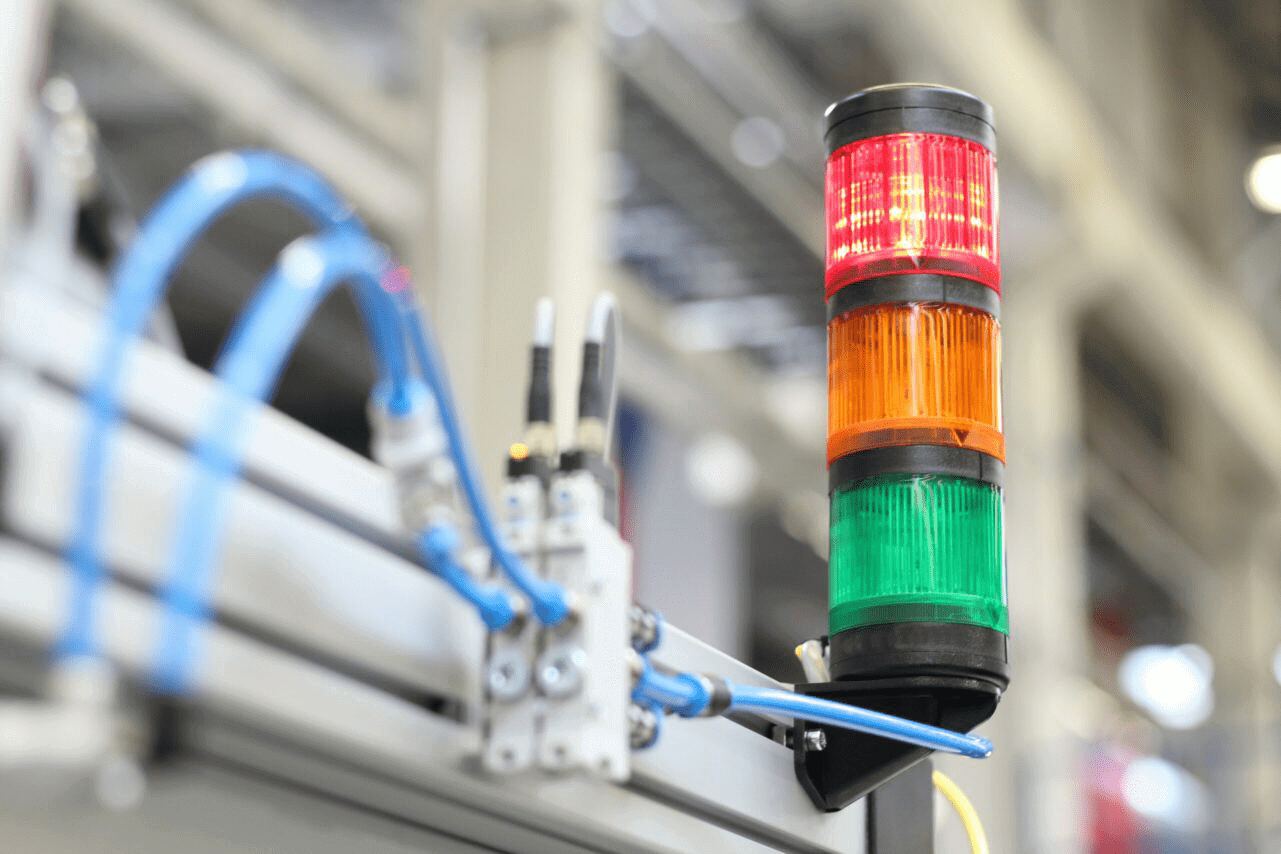

There are essentially two principles to this system: The Andon alerts the human that there's a problem. The Andon allows the human to stop a process and prevent the defect from continuing down the line. How Andon works The word "andon" comes from the Japanese word for a type of lamp.

Andon System? and how it Works? Soft Designers

Andon presentation | PPT Andon presentation Sep 6, 2014 • 8 likes • 4,754 views Download Now Download to read offline Leadership & Management People interested in Lean Manufacturing can learn about the tool known as Andon. R robjfletcher72 Follow Recommended Lean Manufacturing : Concept & Overview [email protected] NareshChawla

Andon System

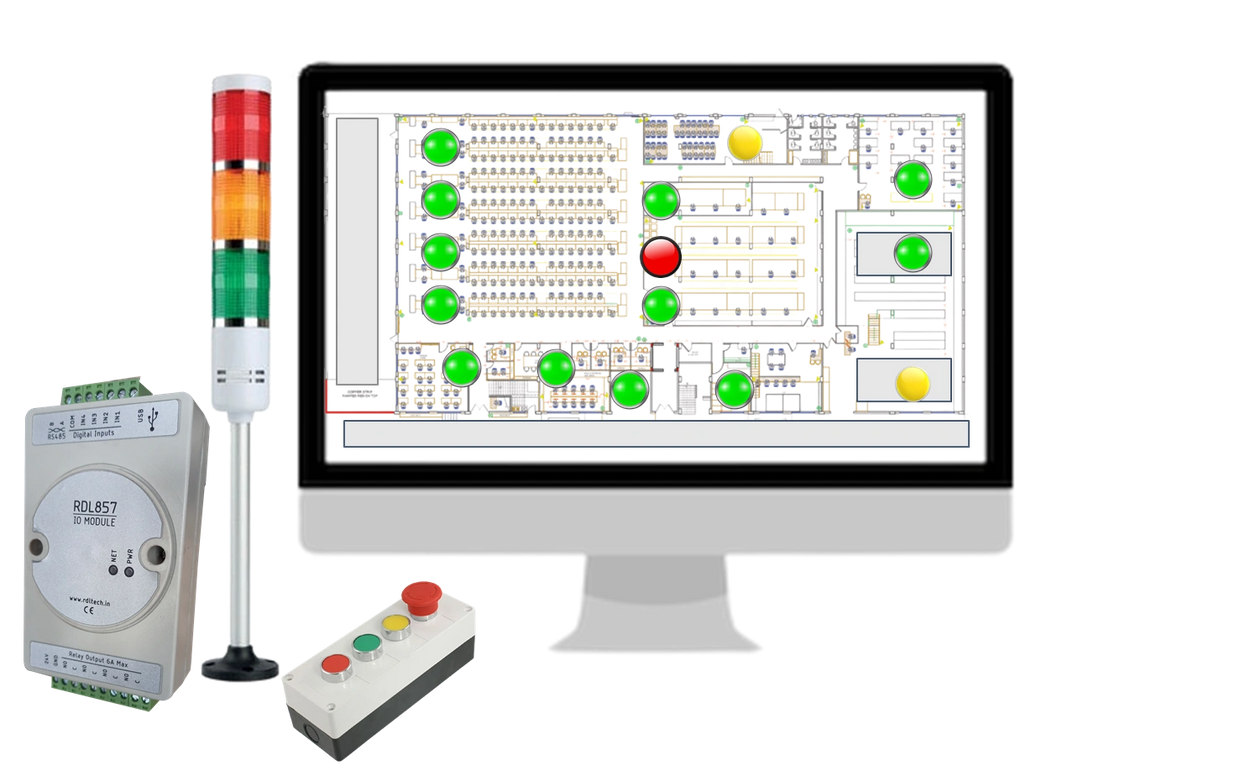

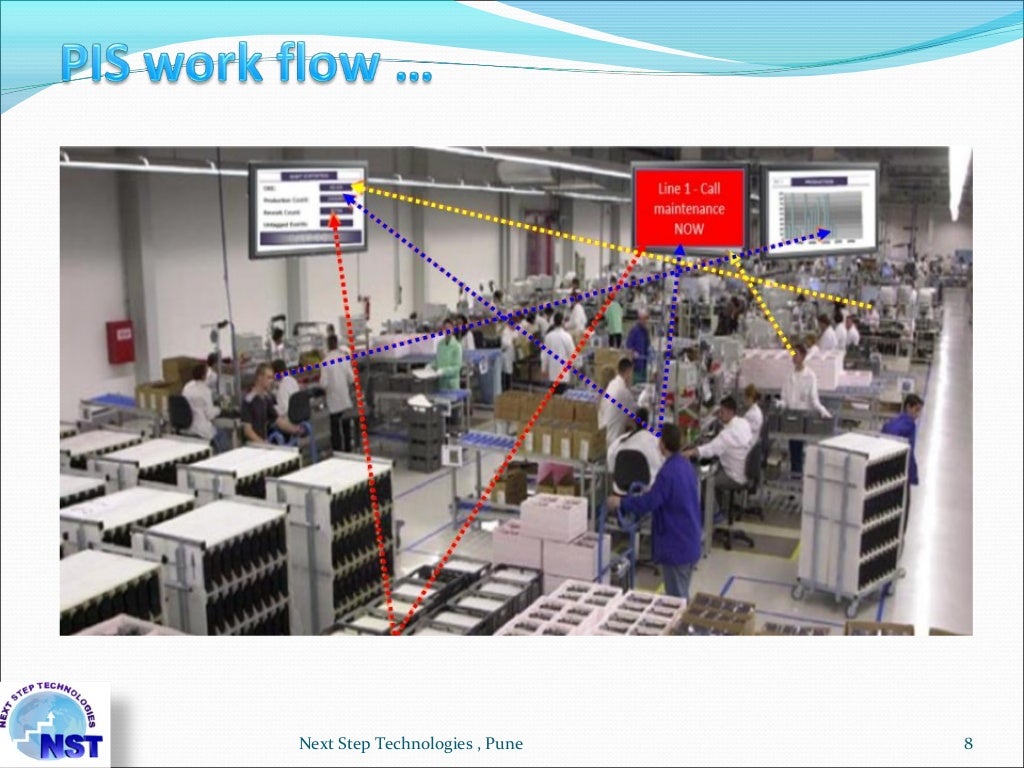

Andons are systems to alert operators and managers about current problems in manufacturing. The system automates the information flow in case of problems. An Andon system usually consists of the actual Andon, sometimes called an Andon board.

¿Qué es y cómo funciona el sistema ANDON? ANK Solutions

Andon presentation robjfletcher72. 4.8K views • 8 slides. Vehicle Manufacturing Automation System, Part 2 - ANDON Tallrain Zhang. 581 views • 22 slides. Visual management Chandradarshan Jain. 2.3K views • 19 slides. Visual Management Mohamed Effat. 9.2K views • 103 slides. Visual Factory Richard Kropman.

PPT COMO OPERAR UM ANDON PowerPoint Presentation, free download ID

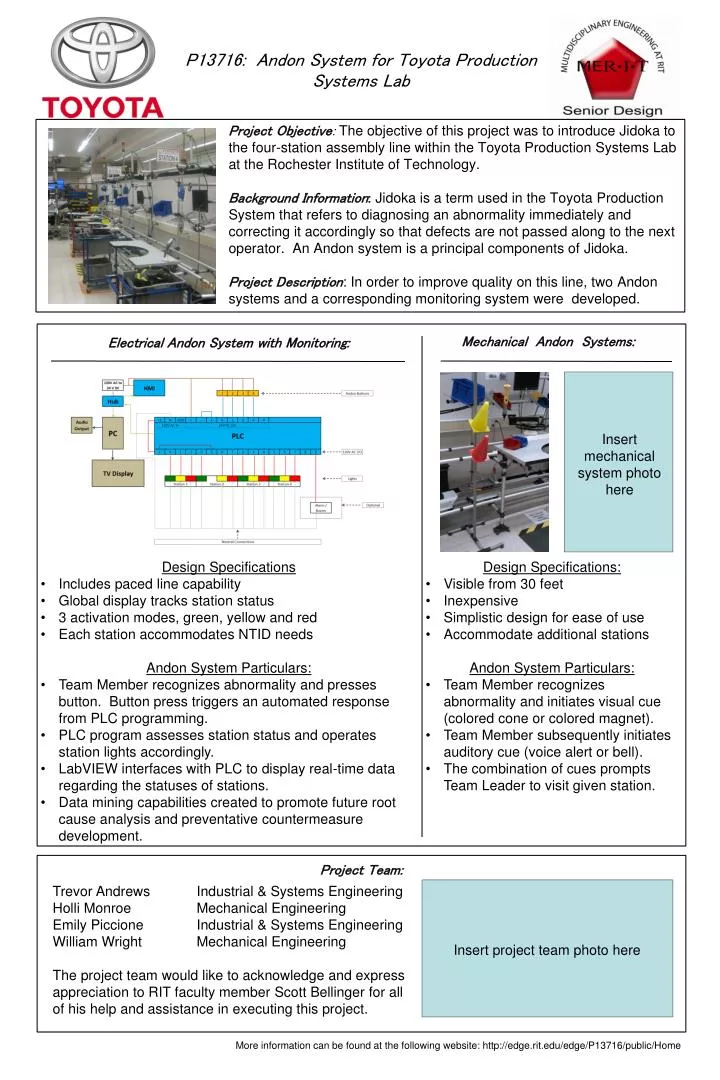

• Design Specifications: • Visible from 30 feet • Inexpensive • Simplistic design for ease of use • Accommodate additional stations • Andon System Particulars: • Team Member recognizes abnormality and initiates visual cue (colored cone or colored magnet). • Team Member subsequently initiates auditory cue (voice alert or bell).

A Guide to Andon in Lean Manufacturing Lucidchart Blog

This slide represents Andon system to evaluate production process status. It includes run time per hour, down time, production line, labor cost etc. Deliver an outstanding presentation on the topic using this Andon System To Evaluate Production Executing Lean Production System To Enhance.

What is the Andon System and how is it Used Latest Quality

An Andon system is worthless without a robust escalation procedure, and this is covered in the course. Extra Info Available Prepared Flip chart Photo Training Matl. Flip Chart Verbal Slide Extra Info Available Prepared Flip chart Photo Training Matl. Flip Chart Verbal Slide Ask the group their understanding of Andon and Andon systems.

Andon System Smart Andon

Andon is a visual management system used by operators and managers in lean manufacturing to easily determine and display the status of production lines. It originates from a Japanese term meaning "paper lantern" with a more accurate English translation as "sign" or "signal" based on the Jidoka methodology of the Toyota Production System (TPS).

Lean Manufacturing & Six Sigma Andon System (行灯 システム) The Real

Features of these PowerPoint presentation slides: This slide represents Andon system to evaluate production process status. It includes run time per hour, down time, production line, labor cost etc. Deliver an outstanding presentation on the topic using this Andon System To Evaluate Production Executing Lean Production System To Enhance.

Andon Efficient Production Alarms Binar Solutions®

Andon is a term developed from Japanese Lean Manufacturing, The term Andon means "Light" or "lantern". It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. The Andon system aims to provide the ability to.

Andon system presentation

Belonging to Lean Manufacturing, Andon is a visual and audible alert system installed in factories to signal failures and inefficiencies in the production chain. It is a coined term of Japanese origin and the system was used for the first time at Toyota. The Andon can be activated automatically or manually to improve efficiency and ensure better management of production downtimes.

Andon Systems

Download .PDF Download .DOC Download .PPT. Andon System. The ever increasing performance requirements and production quality force to introduce solutions enabling. To this end, our system ANDON is designed. ANDON - full control over the production process. Andon term comes from the Japanese language and means "light signals". Andon.

ANDON Monitoring System Sciengate Automation Malaysia

Industrial_Andon_System.pptx - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world's largest social reading and publishing site.

Andon Light System Shelly Lighting

Andon systems are classified into three types: manual, semi-automatic, and fully automatic. Manual Andon System: The simplest type of Andon system is the manual Andon system. A worker physically pushes a button or pulls a cord to signal a problem. The signal can take the form of a light, a sound, or both.

PPT Mechanical Andon Systems PowerPoint Presentation, free download

Features of these PowerPoint presentation slides: This slide represents Andon system to evaluate production process status. It includes run time per hour, down time, production line, labor cost etc. Present the topic in a bit more detail with this Andon System To Evaluate Production Status In Lean Manufacturing Implementing Lean Production.